Products

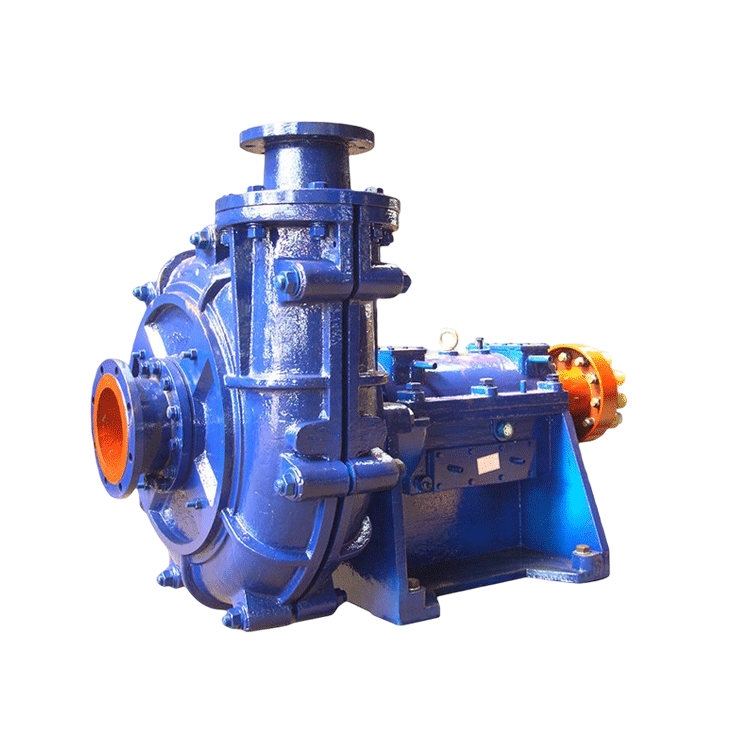

G Gravel Pump

Technical Data• Type: centrifugal• Application: macerator• Media: for gravel• Other characteristics: horizontal• Flow rate: Min.: 36 m³/h Max.: 4000 m³/h• Head: Min.: 5 m Max.: 68 mGeneral InformationThe Milestone G Series Dredge and Gravel pumps is designed to provide continuous

Model:

Send Inquiry

Overview

Technical Data

• Type: centrifugal

• Application: macerator

• Media: for gravel

• Other characteristics: horizontal

• Flow rate: Min.: 36 m³/h Max.: 4000 m³/h

• Head: Min.: 5 m Max.: 68 m

General Information

The Milestone G Series Dredge and Gravel pumps is designed to provide continuous pumping of highly abrasive slurries containing large particles at high maintained

efficiency with low maintenance and ownership costs.

Features

• Heavy duty grease lubricated taper roller TimKen Bearings;

• The special shape of the impeller vanes and casing combine with side sealing vanes to reduce recirculation down the front of the impeller and exclude abrasive solids from between the impeller and casing.;

• The large volume of the casing reduces internal velocities resulting in reduced wear;

• An easily removable shaft sleeve manufactured in either hardened steel or ceramic coated steel with o-ring seals at both ends protects the shaft from abrasive or corrosive contaminants.

Download

Specification

Technical Data

• Type: centrifugal

• Application: macerator

• Media: for gravel

• Other characteristics: horizontal

• Flow rate: Min.: 36 m³/h Max.: 4000 m³/h

• Head: Min.: 5 m Max.: 68 m

General Information

The Milestone G Series Dredge and Gravel pumps is designed to provide continuous pumping of highly abrasive slurries containing large particles at high maintained

efficiency with low maintenance and ownership costs.

Features

• Heavy duty grease lubricated taper roller TimKen Bearings;

• The special shape of the impeller vanes and casing combine with side sealing vanes to reduce recirculation down the front of the impeller and exclude abrasive solids from between the impeller and casing.;

• The large volume of the casing reduces internal velocities resulting in reduced wear;

• An easily removable shaft sleeve manufactured in either hardened steel or ceramic coated steel with o-ring seals at both ends protects the shaft from abrasive or corrosive contaminants.