Products

MAH Horizontal Slurry Pump

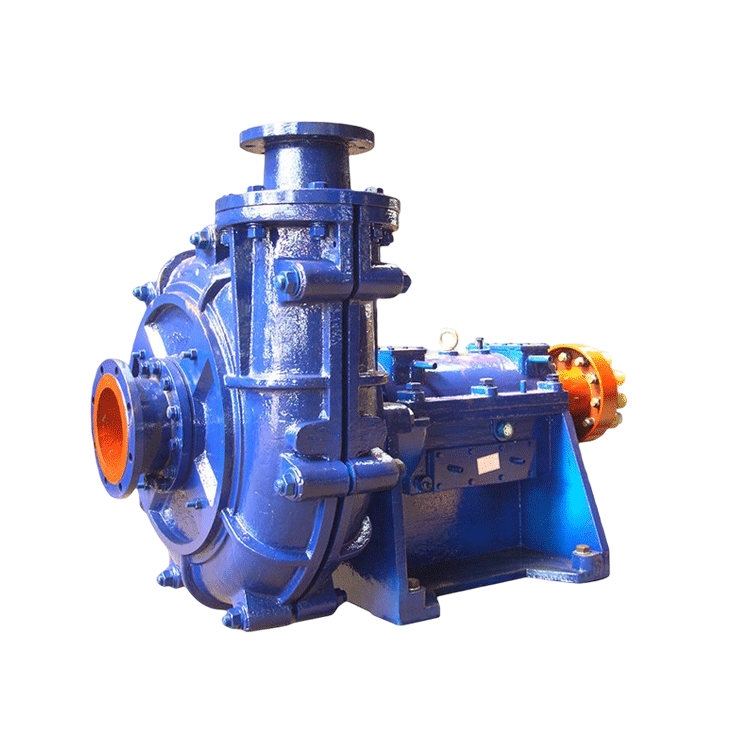

Technical Data• Type: centrifugal• Application: macerator• Media: for slurry• Other characteristics: horizontal• Flow rate: Min.: 3.6 m³/h Max.: 5400 m³/h• Head: Min.: 4 m Max.: 118 mGeneral InformationMAH series pumps are heavy duty horizontal slurry pump designed to handle the

Model:

Send Inquiry

Overview

Technical Data

• Type: centrifugal

• Application: macerator

• Media: for slurry

• Other characteristics: horizontal

• Flow rate: Min.: 3.6 m³/h Max.: 5400 m³/h

• Head: Min.: 4 m Max.: 118 m

General Information

MAH series pumps are heavy duty horizontal slurry pump designed to handle the transfer of abrasive and high density slurries in mining and heavy industry. They are 100% interchangeable with the most common slurry pump design in the mining industry.

Features

• Bearing assembly – large diameter shaft with short overhang minimizes deflection to long bearing life;

• Liners – easily replaceable liners are bolted, not glued to the casing for positive attachment maintenance;

• Casing – Casing halves of cast or ductile iron provide high operating pressure capabilities;

• Impeller – front and rear shrouds have pump out vanes that reduce recirculation and seal contamination;

• Throatbush – wear is reduced and maintenance simplified by the use of tapered.

Download

Specification

Technical Data

• Type: centrifugal

• Application: macerator

• Media: for slurry

• Other characteristics: horizontal

• Flow rate: Min.: 3.6 m³/h Max.: 5400 m³/h

• Head: Min.: 4 m Max.: 118 m

General Information

MAH series pumps are heavy duty horizontal slurry pump designed to handle the transfer of abrasive and high density slurries in mining and heavy industry. They are 100% interchangeable with the most common slurry pump design in the mining industry.

Features

• Bearing assembly – large diameter shaft with short overhang minimizes deflection to long bearing life;

• Liners – easily replaceable liners are bolted, not glued to the casing for positive attachment maintenance;

• Casing – Casing halves of cast or ductile iron provide high operating pressure capabilities;

• Impeller – front and rear shrouds have pump out vanes that reduce recirculation and seal contamination;

• Throatbush – wear is reduced and maintenance simplified by the use of tapered.